Be awesome and support small business. Click for a message from Josh the owner

Knife Blanks

Knife Blanks

Set up a personalized knife shop or get your own personalized knife with each and every detail hand-picked to suit your needs or imagination. Knife blanks are a smart way to achieve good results in the mass production of knives. The "blanking process" is used to make Knife Blanks using any of the methods including water jet cutters, forging or using a metal-cutting band saw.

Knowing More About Knife Blanks

Power of Water: Cut out of a steel bar stock using a water jet, the knife blanks are precisions cut and need a little grounding and heat treatment to turn them into a finished product. With holes and framework for a handle and brass finger protectors in some cases, these blanks can be turned into a masterpiece using plastic, wooden or any suitable handles and fastening them using pins, epoxy, corby bolts etc.

Hardening: The knife blanks are usually hardened for longevity and better edge holding capacity, and annealed in some cases for better results.

Lightweight: The blanks are generally made from lightweight material keeping in mind they have to accompany the owner and to incorporate handles and still maintaining the size to weight ratio in the comfort zone. Generally, a large hollow in the handle along with holes for fasteners and lanyard loops will do the trick.

Knife blanks are commonly used by professional or novice cutlers for creating custom knives and complete the knife-making project in a short period. Many of the knife makers use knife blanks as they eliminate the need for creating a cutting tool from the scratch, offering more room for personalization. Knife blanks are available in a range of designs such as drop-point blades, dagger blades, skinning blades, fixed blades, folding blades, and more; which can be used for creating hunting knives, folding knives, kitchen knives, to name a few. Knife blanks are available in a host of materials such as stainless steel, carbon steel, Damascus steel, and more to cater to varying requirements.

Knife Blanks Product Categories

Knife Blades Boot Knife Blanks: The collection consists of a range of fixed blade knife blanks with full tang and brass guards. The knife-making blade boot knives are available in one-piece Damascus construction and satin to finish stainless steel construction. Most of these knife blanks sport double-edge dagger blades that make them suitable for self-defense knives.

Knife Blades Bowie Knife Blanks: These fixed blade knife blanks are equipped with Bowie-styled blades with a standard edge. Based on the model, these knife blanks stainless steel, carbon steel, and Damascus steel construction. This category includes one-piece knife blanks with full tang and brass guard.

Knife Blades Clip Point Knife Blanks: It includes knife blanks featuring clip point blades and brass guards. These knife blanks are pre-shaped, smartly made using heat-treated and annealed stainless steel which is reputed for excellent edge retention properties. The clip-point knife blanks are great for creating custom knives for chopping, slicing, and cutting jobs.

Knife Blades Damascus Knife: Comprises of knife blades made using top-grade Damascus steel which can be forged into a range of custom designs, to suit user’s requirements. The category also includes clip-point blades, drop-point blades and Coffin Bowie blades – available in stainless steel and Damascus handle construction.

Knife Blades Drop Point Knife Blanks: This category includes a variety of Damascus steel drop point blades which are reputed for their high edge retention and impressive cutting performance. Ideal for creating custom knives, a majority of these blades comes with brass guard for safe carry.

Knife Blades Finger Guards: Featuring an exclusive collection of finger guards, available in different sizes and designs. Knife Blades finger guard sports a brass construction that makes them resistant to corrosive factors. An essential knife-making component, the finger guards are fitted between the blade and the handle to enable easy maneuverability.

Knife Blades Folding Knife Blanks: Consists of a range of folding knife blanks featuring Schrade blades. Ideal for knife makers and knife enthusiasts, these folding knife blanks are appreciated by the users for their great cutting performance and reliable life span.

Knife Blades Gut-Hook Knife Blanks: These gut-hook blanks are a great choice for knife makers and real-life users, who want sharp knives with an outstanding cutting performance. Equipped with stainless steel blades, the blanks are commonly used for manufacturing hunting knives.

Knife Blades Skinner Knife Blanks: Consists of a variety of blanks ideal for making skinning knives. The skinner knife blanks feature fixed blades made from carbon steel and stainless steel. A majority of these knife blade blanks have lanyard holes, finger grooved handles, and drop point blades.

Warranted Against Defects

Knife Blanks are of premium quality and free of any manufacturing defect in terms of material and workmanship. Since these knife blanks are work in progress and not finished products, some might have minor blemishes. This is to be noted that the Knife Blanks are not intended to be used as hammers, chisels, pry bars, or screwdrivers. The repair department will analyze the damage in such a situation and charge reasonable fees for the repairs.

Browse Customizable Knife Blanks at Knife Country USA

Knife Country, USA is a trusted online destination for knife-lovers, camping enthusiasts, and collectors. To make online knife shopping convenient, Knife Country stocks over 30,000 products that are procured from some of the most reputed sellers and brands. The unparalleled range of products available with Knife Country includes camping gear, fixed blade knives, survival gears, and Knife Blanks. Choose from the widest range of knife blanks available in different designs, ideal for creating custom clip-point knives, drop-point knives, hunting knives, skinner knives, and more to suit various preferences. Knife Country USA at delivering products at competitive rates while maintaining the highest standards in service. Our customer services include a convenient shopping experience backed by a 30-day satisfaction guarantee.

In case of any query, connect with us through call (800) 342-9118 or send us an e-mail anytime. We would be happy to handle your knife-related doubts and offer you the best options possible.

Top Selling Knife Blanks

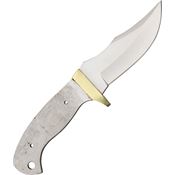

Blank 085 Mod Clip Point Blade Knife

$17.48$12.11Ships FastShips within 1 business day!6.88" overallBlank 005 Clip Point Blade Knife Hunter Knife With Stainless Blade

$13.75$9.53Ships FastShips within 1 business day!7.5" Overall Clip Point Hunter Knife BladeBlank 7709 Brass guard Drop Point Blade Knife

$16.25$11.27Ships FastShips within 1 business day!8.5" Overall Drop Point BladeBlank 016 Blade Knife Utility Hunter With Stainless Blade

$11.25$7.80Ships FastShips within 1 business day!6.88" Overall Utility Hunter Knife BladeBlank 006 Clip Point Blade Knife Hunter Knife With Stainless Blade

$15.00$10.40Ships FastShips within 1 business day!9" Overall Clip Point Hunter Knife BladeBlank 083 Clip Point Blade Knife with Fingergrooved Handle

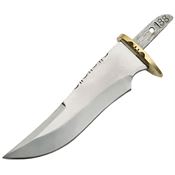

$16.25$11.27Ships FastShips within 1 business day!7.75" overallBlank 015 Blade Bowie Fighter knife Ideal for the Do-It-Yourself Knifemaker

$18.75$13.00Ships FastShips within 1 business day!12" overallBlank 055 Hunter Bowie Fixed Blade Knife

$21.25$13.39Ships FastShips within 1 business day!10.38" OverallBlank 086 Modified Skinner Blade Knife with Fingergrooved Handle

$14.38$9.96Ships FastShips within 1 business day!6.13" overallBlank 087 Small Drop Point Blade Knife

$11.25$7.80Ships FastShips within 1 business day!6.25" overallBlank SOB2 Guthook Blade Knife with Stainless Steel Construction

$29.88$18.83Ships FastShips within 1 business day!5.75" OverallBlank SOB6 Skinner Blade Knife with Stainless Steel Construction

$29.98$18.89Ships FastShips within 1 business day!6.38" OverallBlank 012 Blade Knife Coffin Bowie With Stainless Blade

$18.75$13.00Ships FastShips within 1 business day!12" Overall Coffin Bowie Knife BladeBlank 100 Fixed Blade Clip Point Skinner with Brass Finger Guard

$16.25$11.27Ships FastShips within 1 business day!11" Overall Fixed BladeBlank 078 Knifemaking Boot Dagger Blade Knife

$14.98$10.37Ships FastShips within 1 business day!8.63" overallBlank DM2719 Damascus Drop Point Hunter Blade Knife

$44.88$28.28Ships FastShips within 1 business day!7" Overall Damascus Drop Point Hunter Knife BladeBlank 618 Clip Point Skinner Blade Knife with Carbon Steel Construction

$16.25$11.27Ships FastShips within 1 business day!10" overallBlank 7707 Fixed Blade Knife Medium Boot Knife

$14.38$9.96Ships FastShips within 1 business day!7.88" Overall Medium Boot Knife BladeBlank 7821 Upswept Clip Point Blade Knife With Stainless Blade

$14.98$10.37Ships FastShips within 1 business day!8.25" Overall Upswept Clip Point Knife Blade